Home Page

Contact Info

Order Form

Price List

Handle Info

Shipping Information

Items in Stock

Photo Album #1 - 2013-2014

Photo Album #2 - 2014

Custom Made Wood

Presentation Boxes

Western Kitchen Knives

4" - 6" kitchen knives

7"- 12" knives

Paring knives

Boning Knives

Carving Knife and Forks

Fillet Knives

Steak Knives

La Mezzaluna

Asian Kitchen Knives

Kiritsuke & Sujihiki

Hankotsu

Santoku

Thai Cleaver &

Yasai Bocho

Korean Style

Other Stuff

Wildfire's Reviews #1

Wildfire's Reviews - #2

My Auto Bio

FAQ's

Guarantee

Re-do Older Knives

Custom Set 1

Custom Set 2

Care Instructions

Wildfire in the Media

N.Y. Times article

N.Y. Times Video

L.A. Times

Guardian U.K.

Wildfire in a book

Wildfire & Gant Rugger

More Gant and Wildfire

Wildfire In Austin

Just for Fun

|

My Basic Autobiography

2014

|

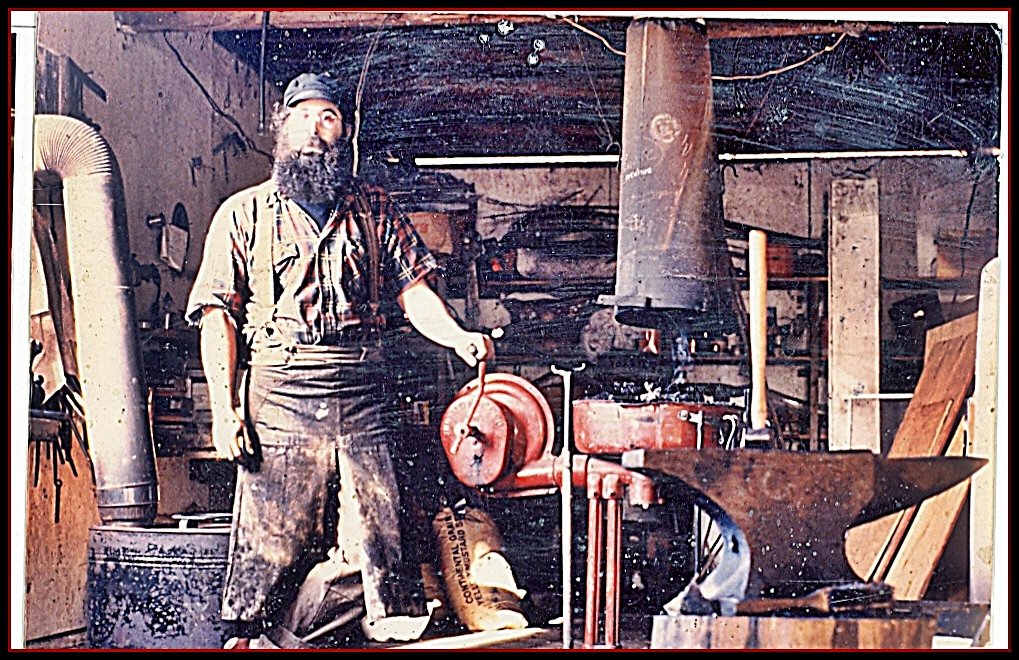

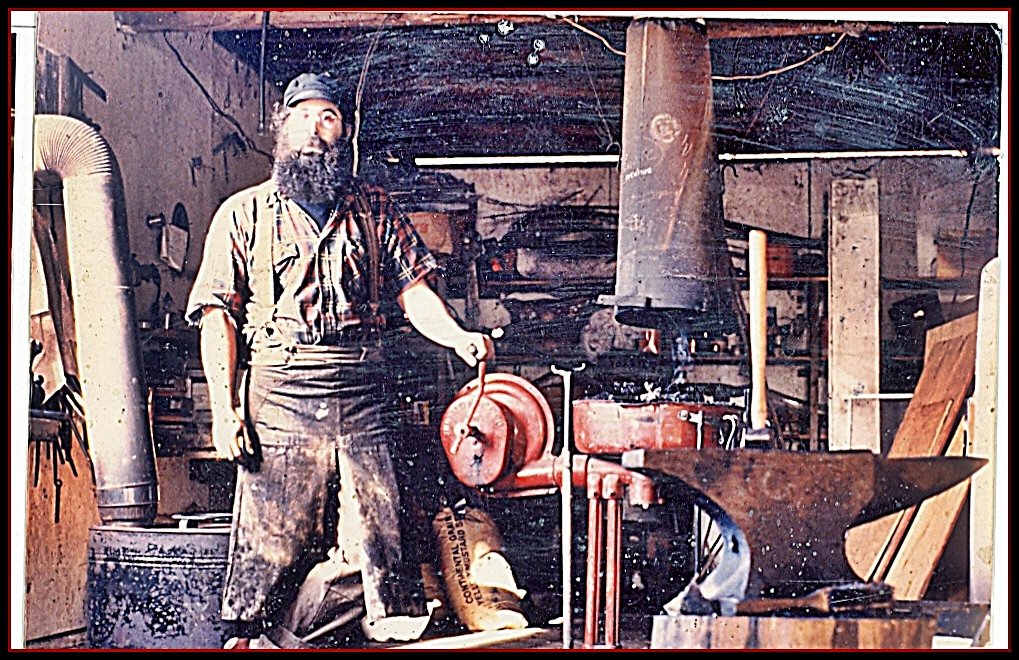

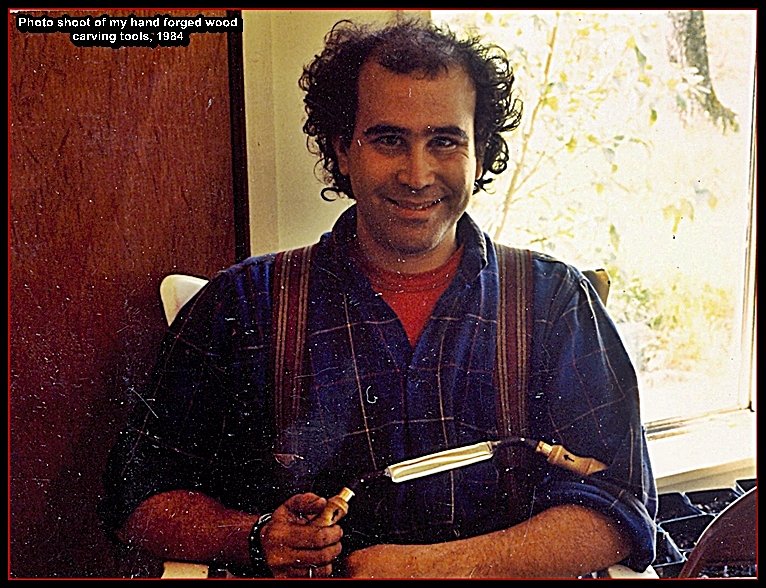

Me at the coal forge 1983 -notice hammer and anvil where I labored for years making house jewelry and wood carving tools. This was on a 350 acre sheep ranch, where I lived and looked after a 150 head of sheep.

Lunch break

|

I'm grew up in Brooklyn, mainly in West Brighton Beach in Brooklyn.

After finishing my masters degree in Individualized Education (Open Classroom), I left NYC after an epiphany and headed westward to complete my life's journey. Three years later my friend and local smith, the late Jim Rich, offered me an open ended apprenticeship after I paid him for a three week class.

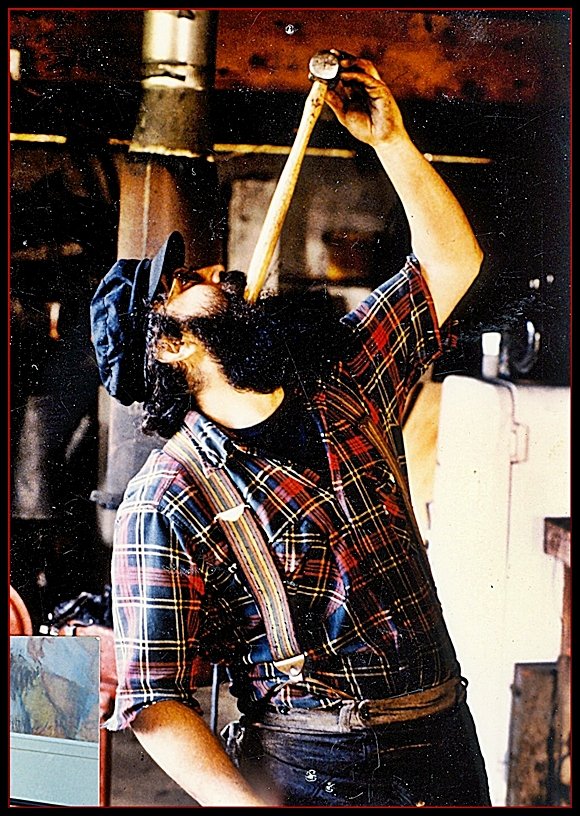

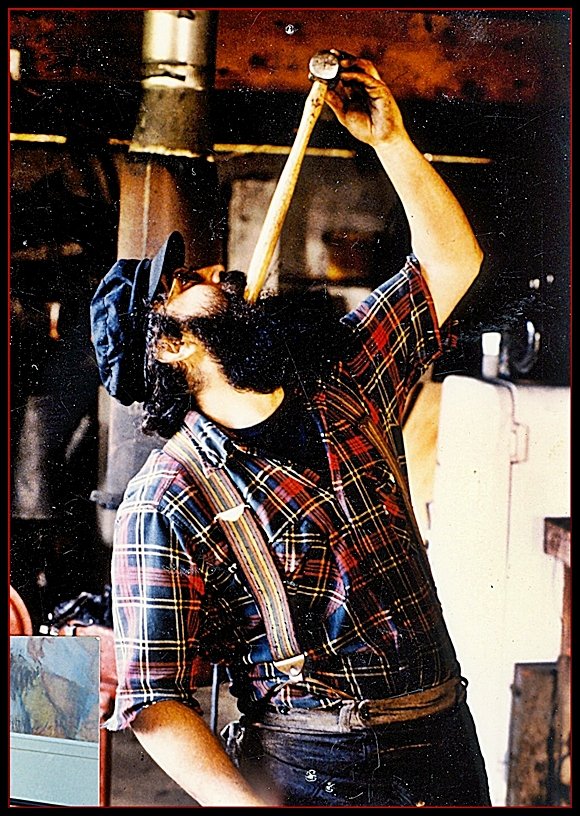

I lived at the forge, swung a sledge hammer when called for, and learned all aspects of forging and smith-ing in a non electrified shop. I lived next to the forge in a log cabin without bathroom, power or water and worked 7 days a week for 9 hours a day, which was my choice.

I learned forging techniques and design, as well as horse shoeing and wagon making. I loved forging the most, and was determined to not only master the skills and designs involved, but refine my skills over time.

After finishing this apprenticeship, I made forged "house jewelry" for three years, selling my work at low end craft fairs. Another fork in the road came up again, when one choice was to borrow a bunch of money and get into gates and grilles as a specialty welder/smith or go deeper into forging by pursuing work forging wood carving tools. This meant forging tool steel, which is much more delicate than the mild steel I had always used.

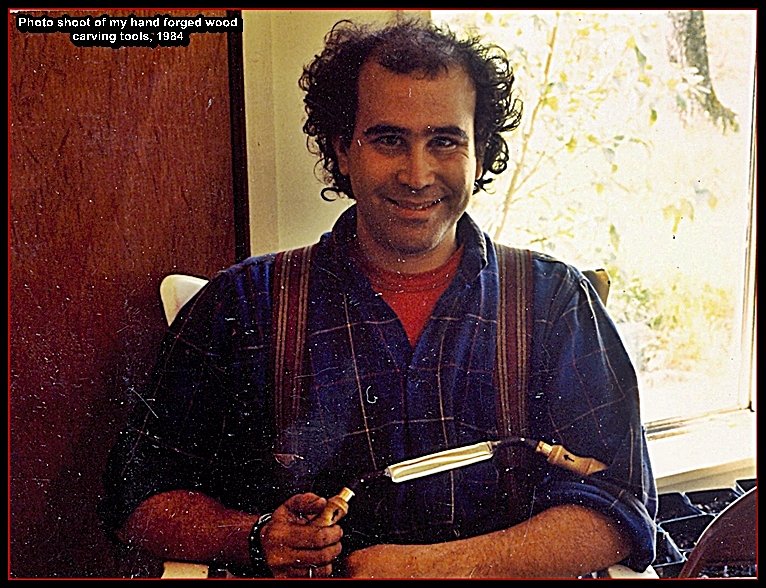

At this point I decided to go for it and refine my forging skills by working with tool steel , and spent a few amazing days with a master tool smith who forged a beautiful line of wood carving tools that were so fine. His name was Dick Anderson from Washington state and I salute his fine craftsmanship.

After this amazing meeting, I spent 2 years of my spare time getting ready to produce those fine woodcarving tools. These were fully forged, by hand, from round high carbon tool steel. This meant that I had to make a line shaft, without a design. After making the line shaft, which took a year of weekends , I had to figure out how to use it so that I could grind, polish and buff the tools which I had just forged. So I needed to find and buy the equipment to place on the machines I made, and then master the skills of using that equipment . This meant figuring out what size buffs to buy, what buffing compounds to use and how to use them . Then there was the carving tool designs themselves to figure out, and of course then I needed to use them a lot to figure out what needed tweaking where. Without a retired good hearted Army mechanic who generously offered me his time to help this along , this would never have happened. So it not only became a learning curve for my craft, but I also got to know this rare generous good hearted man named Charlie Hoover.

As soon as I needed to create something new, another experienced old timer stepped in to help. He was a retired mill wright with time on his hands, and we had fun together. His name was George Gallios. May he rest in peace.

He helped me make dies for creating wood gouges. When I had all my tools lined up, then I could begin to master the designs and actual work. All in all I invested 3.5 years mastering this difficult craft and making the transition to tools. This transition was made much more difficult by having no one to question or even a book to turn to ( no internet yet ) . Then I made these tools full time for 7 years. These included, in all sizes - traditional and modern adzes { learned from a Kahune' in Hawaii}, chisels and gouges, scorps, draw knives, 15 different carving knives, and many other specialty tools for violin makers, log cabin builders, etc.

It was a natural leap for me to make kitchen knives from here, as people at my now high end art shows often visited and encouraged me to copy their knives. After making so many forged tools from carbon steel, I fully believed through experience that stainless steel was good for blender parts, but not appropriate for edge tools. So I became a maker of carbon steel kitchen knives.

I also hold a Masters Degree from CCNY in Individualized Education, taught kindergarten and college for years, have an AAS degree in accounting, am a trained Tax expert and paralegal, am a certified hypnotherapist (Alchemical Hynotherapy) and the happy papa of a 14 year old brilliant beautiful healthy daughter named Zoe.

Copyright held by Michael Moses Lishinsky � 2014�

All rights to all text and images on this web site is

copyright protected via the Digital Millennium

Copyright Act. Click here to download a

pdf copy of full warning. |